A hydraulic manifold is normally responsible for regulating fluid flow between a number of pumps and actuator and many other components throughout the normal hydraulic system.

This is often equated to a switchboard within a regular or day-to-day electrical circuit given it enables you because the operator to manage the volume of fluid flowing between the various the different parts of your hydraulic machinery or equipment.

A practical application is in a backhoe loader, the place where a manifold can make don and doff to divert the flow of fluids for the telescopic arms of both the back and front buckets.

The operator’s cabin may from the cause of connecting the manifold to the levers to enable them to be employed to attain the right manifold behaviour.

Assorted hydraulic valves interconnected to one another may also form a manifold. Within a manifold, complex control behaviour is enabled from the multiple mixtures of various states from the valves.

How a Hydraulic Manifold Functions or Works

The standard objective of a hydraulic manifold is to distribute hydraulic oil within a given circuit. Hydraulic valves distributed through the entire manifold often regulate the flow and distribution of pressurised oil, that’s channeled through hoses of an particular work device, including a hydraulic cylinder or motor.

Apart from the organised and logical layout provided by a manifold, it may also help to consolidate components within itself to minimise space. Other advantages include pressure drop, less assembly time required, fewer fittings required and minimised leak points. A hydraulic manifold could be equated into a black box, where troubleshooting can be a concern. However, a correctly designed system with test point in strategic or key locations, locating or identifying the challenge could be a lot easier or faster. Connecting a transducer to such test points, it becomes very easy to link the information to the machine PLC as well as display them with all the HMI.

Application

Hydraulic manifold applications typically include material handling/ production equipment, machine tools, food processing, heavy construction equipment, off-highway equipment, farm equipment, oil field equipment, valve operations, plus more.

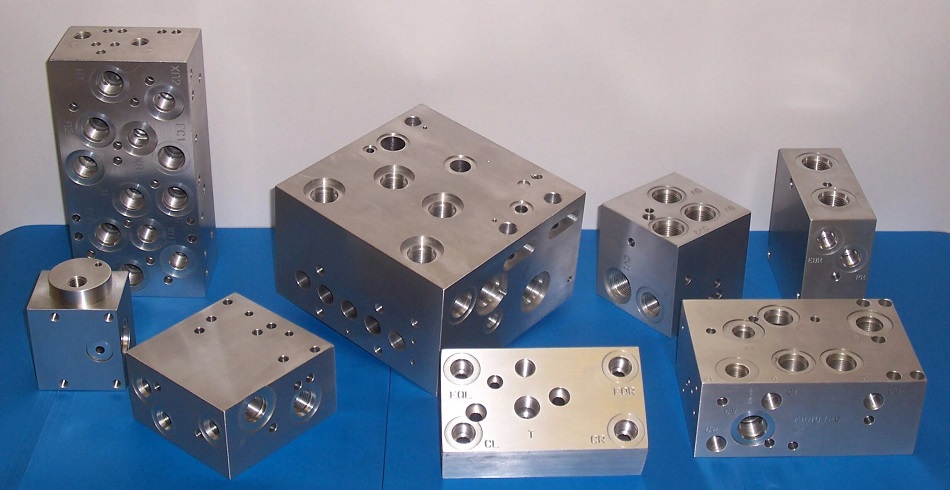

Manifolds appear in two basic designs: mono-block and modular-block designs. The first sort holds passages as well as valves for the whole system whereas rogues supports 1 or 2 valves, with interconnecting passages for the relevant valves and flow-through provisions.

To constitute a complete system, a modular block is normally linked to a few other modular blocks.

Conclusion

Because there are numerous configurations application towards the manifold design, the engineer has lots of software products at her or his disposal to assistance with designing a system. Advances during these packages and technology have enhanced the operation and treating hydraulic manifolds.

For details about CETOP 3 standard hydraulic manifolds go to our new net page