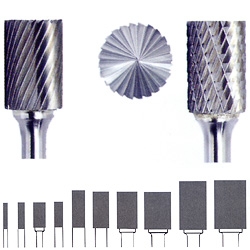

Carbide burrs: exactly what are they?

Simply said, carbide can be a strong combination comprised of many elements, including carbon. Additionally, high-quality tungsten is normally employed to make carbide burrs once it has been heat-treated. Tungsten is much more rigid than steel, therefore carbide burrs can trim through hard metals quicker. Tungsten carbide, metallic which is exceptionally strong which enable it to tolerate high temperatures (approximately 3 times stiffer than steel), could be the materials used to generate carbide burs. Carbide burs are able to keep a pointy leading edge and stay used repeatedly without losing it thanks to their toughness. Carbide burs, however, are brittle where you can propensity to shatter under stress. Make sure you operate them lightly possibly at high speeds.

Carbide rotary burrs, also referred to as rotary files or die grinder bits, bring shaping, grinding, and removing burrs, burs, and sharp edges from materials (deburring).

The most prevalent uses of carbide burs will excavate and prepare cavities, finish cavity walls, complete restoration surfaces, drill old fillings, finish crown preparations, shape bone, remove impacted teeth, and separate crowns and bridges. Their heads and shanks identify burs created from carbide. What sort of shank is required depends on the hand piece being utilized. The type of cutting design or head shape used is determined by the process being completed.

Uses of Carbide Burr

5 most frequent applications for carbide burrs are listed below:

Clipping the impeller runners, as with car engines.

Processing pipes, polishing the top of inner holes on mechanical components, and routing and groove processing of assorted mechanical parts, such as machine makers and repair centers.

To end machining the chambers of metal moulds, like shoe moulds.

For handmade presents, they carve various metals and non-metals.

Cast, forged, and welded components, like those present in machine foundries, shipyards, and car makers, really should have their flashes, burrs, and welded seams removed..

Advantages of Carbide Burrs

Carbide tools give a quantity of benefits, that are the following:

Carbide burrs are ten times extremely effective at machining than a manual file and almost significantly more effective than the usual tiny grinder wheel having a handle.

Burrs created from carbide cut processing costs overall.

To scale back dust pollution, the burrs use a handle to exchange the tiny grinding wheel.

When machining mould cavities with extreme accuracy, carbide burrs assist in producing link between the best caliber.

Carbide burrs are 200 times stronger than tiny grinding wheels and 10 times better quality than high-speed steel tools.

Utilizing carbide burrs is easy, dependable, safe, and simple.

Iron, steel, carbon steel, metal, marble, jade, copper, aluminum, and alloy steel can all be helped by a carbide burr.

To get more information about carbide ball burr see our internet page