There are many labels by which the centrifugal pumps are recognized including the hydrodynamic water pump and also the active stress push. As the name suggests, the pump is manufactured using the basics of centrifugal force in consideration. The kinetic vitality made as a result of rotation from the turbine or electronic generator/electric motor is turned into pressure from the water and therefore the stream takes place.

Advantages Of Centrifugal Pumps

When comparing these pumps in tandem along with other pumps, they may be easier-to-mount. These are constructed by way of the entire process of again pullout-design and style. In times of fix, the parts can be used apart, set and function restarted in just a short duration. But, you want the help of an experienced to get the best.

Device

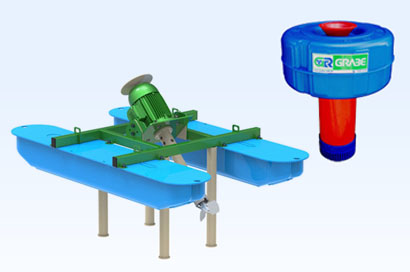

The duty of moving any liquid is done with the impellers. The most important element is of course, the mechanical seal that stops the essential fluids from seeping externally from the insides of your centrifugal pump.

The main entire body of a centrifugal pump is made up of impeller, push axis, bearing, stuffing box, close diamond ring and pump motor system.

Considering that the method involves movement of essential fluids, a great deal of strain must be dealt inside the push. The leakage of fluids can happen if the components are not properly attached. The mechanised closes existing between your moving shaft and house aid in maintaining a tab about the pressure triggered as a result of rotation of shafts. The seals vary in size and functions as they are designed as per the industry and their work function, however.

Businesses

Various kinds of industries use centrifugal pumps and they also vary right from environment plants, textile businesses, potential stations, food sectors and water desalination vegetation.

Centrifugal pumps may also be manufactured the very best use of in large backyards or water ponds.

Variety Of Inferior High quality Seals

Just imagine the catastrophe that can be caused if the leakage happens. There might be loss of life and resources.

Problems

Naturally the electric motor will be affected as the impeller will get affected if you have got an inexperienced operator. In such a case, a speedy activity is important.

If the centrifugal pumps displays signals of vibration and gives noise, then the impeller has become eroded. Several of the debris could have entered the impeller as well as the end result is rust. The impeller must be changed for correct operating from the centrifugal push.

It is necessary that the pump be heated so that the flow is smooth if there is low pressure in the pump or low level of chemical fluids.

Impeller are not properly aligned, there can be un-balancement, if the shaft. The pump motor might shake extensively and also the outcome is going to be other regions can get loosened, as well as the overall parts are affected harm.

For more info about grabe.ind.br please visit net page: look at more info.